Siemens Launches Thermal Analysis Software for the 3D IC Design Era

The new EDA tool supports the industry’s growing transition toward 3D integrated circuits.

Siemens has launched its Calibre 3D Thermal software to provide chip and package-inward thermal analysis for 3D integrated circuits (ICs). This release fills an EDA gap for 3D ICs, which stack multiple layers of silicon wafers to enhance performance and reduce footprint. Vertical integration requires advanced simulation and design software tools, especially when it comes to thermal analysis.

Calibre 3D Thermal software

All About Circuits interviewed Siemens' representatives for Calibre Design Solutions, John Ferguson and Michael White, to learn about the release firsthand.

A New Thermal Simulation Tool for ICs

Siemens designed its Calibre 3DThermal to address the emerging design and verification challenges that range from early-stage chip exploration to final design signoff.

“The whole focus of this is to help designers implement, validate, and analyze their designs much earlier in the life cycle of the overall product versus waiting until the end and having surprises that are difficult to deal with once most of the design has been implemented,” White said.

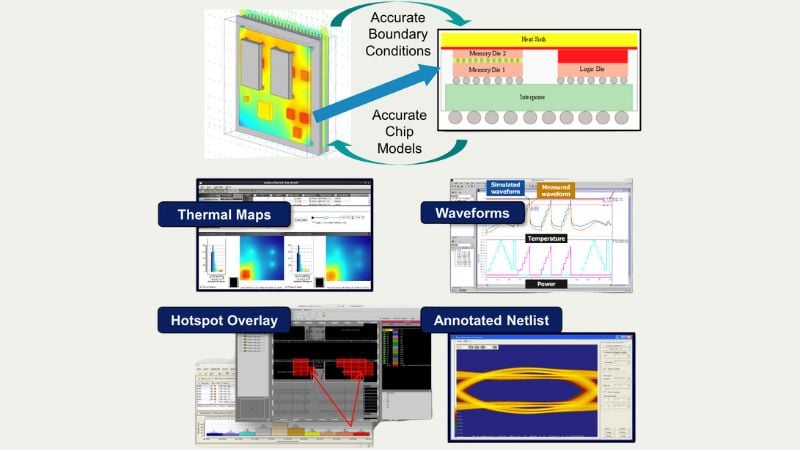

By incorporating elements of Siemens’ Calibre verification software, Calibre 3DSTACK software, and the Simcenter Flotherm software solver engine, Calibre 3DThermal enables engineers to rapidly model, visualize, and mitigate thermal effects in 3D-IC designs.

“We consistently hear that we’re easy to use, especially for early feasibility analysis,” White said. “The software's advanced automation enhances designer productivity by automatically creating thermal models, gridding, and time step generation.”

Automation features empower designers to start with minimal inputs for initial feasibility studies and progressively refine their analysis as more detailed information becomes available. Such flexibility helps thermal analysis be more easily integrated into the IC design flow.

Calibre 3D Thermal user interface.

Beyond user-friendliness, Calibre 3DThermal supports accurate simulation by embedding a custom version of Siemens’ industry-trusted Simcenter Flotherm solver engine.

“We leverage the accuracy of a product that's been proven in the industry,” Ferguson said. “The tool generates precise chiplet-level thermal models for both static and dynamic simulations of full 3D-IC assemblies.”

To this end, the software can import precise boundary conditions from Flotherm and generate detailed die thermal models that consider non-uniform thermal properties caused by metallization and through-silicon vias (TSVs). Fine-grain power maps can then capture hotspot effects and report temperature gradients, ensuring that designers can confidently address thermal challenges.

Thermals in a 3D IC Era

3D integrated circuits stack multiple layers of silicon wafers or dies in a single, compact device. Unlike traditional 2D designs, where components are spread across a single plane, 3D ICs interconnect layers through vertical vias or through-silicon vias, which enables higher transistor density and more powerful devices. However, device thermals have a more profound impact as devices become denser. With more transistors operating in a smaller space, power density starts to impact device reliability and lifespan.

3D ICs versus 2.5D ICs

“Thermal starts to become pretty interesting when I'm stacking things vertically,” White said. “Thermal and stress interact with each other. Thermal and power interact with each other. Ultimately, you need to start thinking about the high-density package or assembly you're delivering with those three things from a multi-physics perspective.”

With 3D ICs, managing heat dissipation becomes necessary to ensure performance, reliability, and manufacturability. Waiting until the final assembly to identify and correct thermal issues can severely disrupt design schedules. Calibre 3DThermal mitigates this risk by performing iterative thermal analysis at various design stages, thereby reducing the likelihood of functional or scaling issues at the final tape-out.

All images used courtesy of Siemens.