Power-Dense Microcapacitors Pave the Way for On-Chip Energy Storage

In an early look at on-chip power, researchers have demonstrated that thin-film micro-capacitors can be fabricated on semiconductor chips.

Much of what was once external to the microprocessor has been integrated. Today’s chips have analog-to-digital converters (ADC), digital-to-analog converters (DAC), capacitive touch input, comparators, and a host of other peripherals built in. Some even come with small field-programmable gate array (FPGA) sections. However, the power supply is still always external.

That may soon change. Scientists at the Lawrence Berkeley National Laboratory (Berkeley Lab) and UC Berkeley have developed a thin-film storage capacitor that can be fabricated directly on top of a microprocessor.

_and_Nirmaan_Shanker_from_Berkely_Lab.jpg)

Sayeef Salahuddin (left) and Nirmaan Shanker from Berkeley Lab

With the extremely small power requirements of many modern microcontrollers, this new prototype could lead to devices that can operate without external power sources.

Why Are Capacitors in Silicon So Difficult?

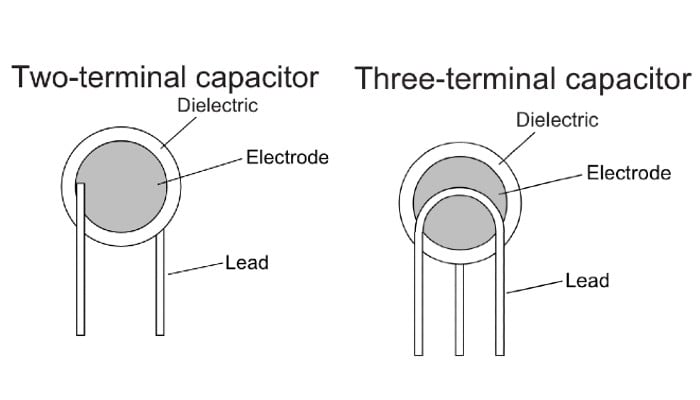

Capacitors store energy through an electrostatic charge. This differs from a battery, which uses electron movement through molecular chemical constructs. A standard capacitor is built with two conductive metal layers separated by an insulating layer called a dielectric. The dielectric can be just about any insulating material, including air. The thickness and physical size, among other properties of the dielectric, determine the capacitor’s ability to store charge.

A capacitor's simple three-layer construction makes it a more attractive power storage device to integrate than a complex electrochemical battery. Capacitors also have a long life, no risk of chemical leakage, and fast charge/discharge ability.

Structure of a two-terminal and three-terminal capacitor. Image (modified) used courtesy of Murata

Integrated circuits typically don’t have capacitors built into them, with DRAM cells being one of the few exceptions. The amount of space required for a capacitor is prohibitive. While it's not difficult to integrate these devices, it is resource expensive. A capacitor's power-to-size ratio makes it challenging, if not impossible, to place inside of an IC. Capacitors in silicon work in a DRAM cell because the energy storage requirements are so low, and the DRAM refresh cycle delivers regular maintenance power.

Negative Capacitance to the Rescue

Berkeley Lab scientists have been studying negative capacitance materials to lower threshold voltages for MOSFET transistors. They discovered that relative to energy storage, putting one layer of negative capacitance dielectric on top of a conventional dielectric layer increases the capacitance. While two layers of conventional dielectric decrease capacitance, one negative and one conventional dielectric layer has the opposite effect.

Thin-film energy storage capacitor.

With positive capacitance, increasing voltage increases the charge in the capacitor. With negative capacitance, a change in charge causes the voltage to change in the opposite direction. A drop in voltage increases the charge. This effect somewhat resembles the charge resulting from a collapsing magnetic field in an inductor.

The negative capacitance dielectric is composed of hafnium dioxide and zirconium dioxide (HfO2-ZrO2 or HZO), known as an antiferroelectric thin film. The mix of HfO2 and ZrO2 is grown directly on silicon using atomic layer deposition, a process now common in the chip fabrication industry.

The Prototype's Energy Storage Density

The team found record-high energy storage density (ESD) and power density (PD) with their research devices. Part of the ESD comes from the material, and part comes from the construction architecture. The HZO capacitors are grown as layered films in deep 3D trenches with aspect ratios of up to 100:1. The construction is inspired by DRAM capacitors, which also use the deep 3D trench.

The result is a microcapacitor with record energy density compared to conventional electrostatic capacitors. The in-chip caps demonstrated an energy density of 80 mJ-cm-2 (9x) and a power density of 300 kW-cm-2 (170x).

Chip-Integrated Capacitor for IoT

The researchers' ultimate goal is to create low-power silicon chips that do not need external power storage. Many small systems, such as remote sensors and IoT devices, spend most of their time in deep sleep mode, only needing power for short bursts. Capacitors are ideal for such applications.

While a chip-integrated capacitor may not have the overall energy capacity of a larger conventional battery or large external capacitor, it can deliver its power quickly, meeting the short-burst mode power requirements of many remote edge computing agents.

Its integration directly into the silicon significantly reduces transport and conversion losses. Combining ultra-low-power silicon with on-chip power can potentially create a new class of remote devices with smaller sizes and lower costs than what is possible today.

All images used courtesy of Berkeley Lab.